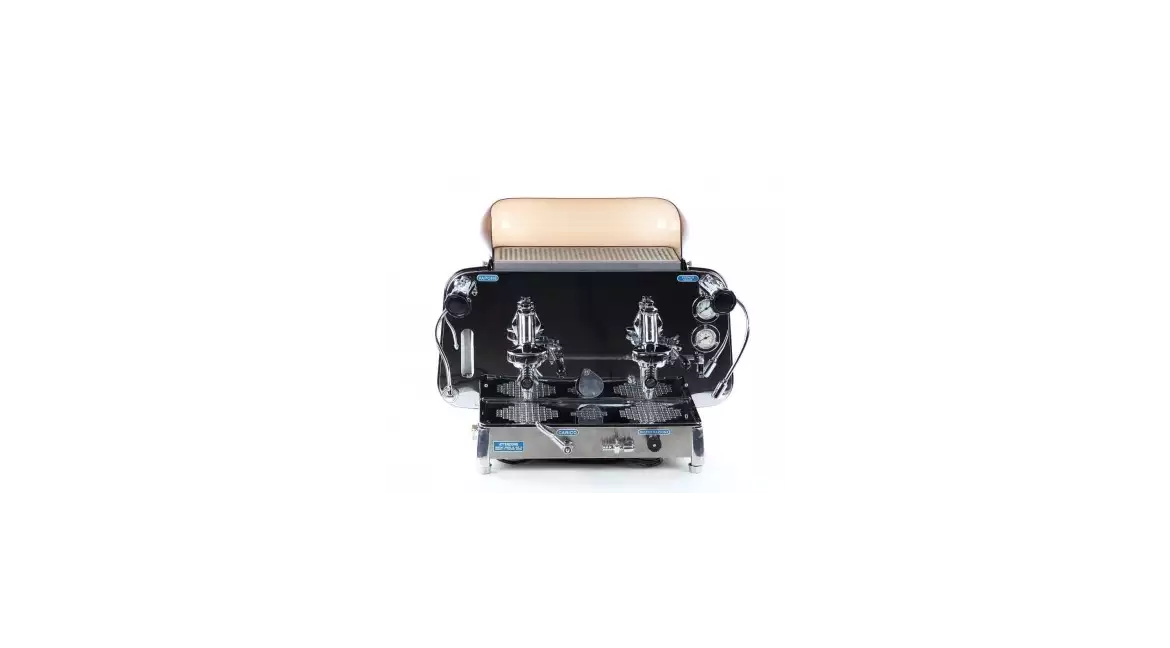

Faema E61 espresso machine

Faema E61: The most famous espresso machine in the world.

The life of the E61 began in 1961 and it is considered the first modern espresso machine. By which it was possible to exert constant pressure on the coffee, in contrast to the pressure exerted by the springs in lever espresso machines. The difference between a lever brewing group and an E61-style brewing assembly was discussed in a previous blog post.

The individual components of a Faema E61 and how they work.

Non-return valve, rigenerazione valve, and over-pressure valve

The non-return valve is the first valve body that hits the water as it enters the machine. It all starts with a fitting on the side of this valve. This pipe leads to the other side of the machine. First, it goes to the Faema E61 pump gauge, then it goes to the rigenerazione valve. If you want to use a new water filter, you must first rinse a certain amount of water here. If you open this valve before starting to rinse the water filter, this water will not get into the machine.

In this valve body, a T-piece is screwed. One side goes to the HX in the brewing group. The other side goes to the boiler filling valve. The T-valve and the valve body are actually check-valves. Thus, the heating water from the HX cannot flow back.

Filling the boiler

Filling the boiler with a Faema E61 espresso machine is pretty straight forward. The machine will fill with water pressure from the water line, not the pump when you lower the aluminium lever on the front of the machine. As a result, the filling valve is opened. By opening the fill valve, you can see the water rising in the sight glass on the left side of the machine.

The filling valve itself is a basic valve. The valve consists of the following components:

- Valve body;

- Valve shaft,gaskets,springs, and aluminium filling lever;

- Gasket holder, gasket and valve spring;

- And of course, the flat seals to make it a watertight system.

The boiler

During the production years of the Faema E61, you see a variety of boiler types passing by. All with their own configurations.

Open style copper boiler

The early models had an open tube system. This means that the boiler itself was a tube with flanged edges. At these edges, there was a separate boiler flange. One for the heating element side and one for the water level on the filling side.

The boiler was assembled from outside to inside as follows:

- Aluminium boiler ring;

- Copper boiler flange (depending on the configuration, on which side);

- Flange gasket;

- 2 half aluminium rings;

- All this was held together with 12 nuts and bolts.

For the single group, a machine was also produced that had only the heating element side flange

The stainless steel models

There are 2 stainless steel boiler models for the Faema E61. Both boilers are made entirely of stainless steel. The first is completely enclosed with fixed flanges. The other model has a flange on the heater side.

The problem with these stainless steel boilers is that they are prone to corrosion, although stainless steel is corrosion resistant in many situations. However, the combination of chloride and the working temperature of an espresso machine is not ideal. Because these factors can cause cracks and pitting. For stainless steel boilers, proper water filtration is key.

1 side open copper boiler

Some of the later models of the E61 had a copper boiler closed on one side and open on the flange side, the side of the heating element. The mounting on this flange side was as follows:

- Aluminium boiler ring;

- Copper flange;

- Gasket;

- And the soldered flange on the boiler

Some of these copper boilers for the 2-group machines had a large HX in the middle for 2 groups.

HX system

The Faema E61 was the first espresso machine to use a heat exchanger (HX) system. Originally with the lever machines, this was a dipper system. How does an HX work? In short, the water flows through the HX on the way to the brew group, which is heated by the water in the boiler.

For the Faema E61, there are a variety of HX systems. The most commons are the diagonal tubes located in the middle of the boiler.

Heating element

For all Faema E61 the same heating element type was used, a flanged one with 2 bolt holes. Currently, there are still some versions with the following specs in production:

- 1-group flanged 1500W 230V and a 110V version;

- 2-group flanged 2600W 230V, 110V and a 380V version;

- 3-group flanged 3700W 230V and a 380V version;

- 4-group flanged 5000W 230V and a 380V version.

These heating elements are sealed with a PTFE or a fibergasket.

Pressure switch

The Faema E61 also used a pressure switch, initially with mercury-filled switches. More details can be found in our other blog post: (-)

Sight glass

The sight glass of the Faema E61 is located on the left side of the machine. The front panel has an opening for a good view of the water level. The sight glass assembly is a fairly simple assembly:

- Sight glass bracket;

- Lower and upper fitting, which is connected to the sight glass bracket with a few nuts. These fittings are not identical because one contains a small steel ball;

- Sight glass and flat gaskets. These gaskets are fixed with a brass cup. In order to give equal pressure to the whole gasket, there is a sight glass spring installed on both sides. And to keep everything in its place there are 2 fittings placed over the sealing components;

- In order to make the water level of the Faema E61 sight glass easier to read, a white cover is placed on the back.

The tubes from the sight glass are connected with a lower and an upper tube on the left side of the boiler or on the left boiler flange.

Steam and water valves

The Steam and water valves for the machine are located on each side of the machine and their valves are identical. The only difference between the water and steam valve is that the connection on the boiler has a hose that reaches to the bottom of the boiler. The fitting on the boiler is just a regular fitting so that the compressed air is discharged.

What makes the difference between the water and steam pipes? Well, the ends of the tubes. One has a steam peak and the other is suitable for water.

Faema E61 brewing group

The Faema E61 brewing group is up to this day the most frequently used espresso machine brewing unit. Over time, there have been some modifications, but the principle remained the same. It is a manually operated brewing group. In the newer versions of the Faema E61, there is also an electronically controlled brewing group.

The brewing group has 5 sections, next to the main body, that play an important role in the working of the brewing group:

- Gigleur section;

- Top trumpet;

- Group collector;

- Drain valve;

- Lever assembly.

Gigleur section

This part of the brewing group is assembled above the top trumpet. On the top of thetrumpet, a gigleur is screwed in. To prevent this gigleur from blocking, there is a wire mesh holder which also functions as a spring guide to keep thegigleur. This is usually always sealed with a PTFE gasket and finally, the assembly is closed with a 3/8 nut.

Top trumpet

This part is screwed into the brewing group body itself. It contains the brewing valve assembly. It is assembled with a round rod, which is screwed into the gasket holder, the gasket of course, and the valve guide. These valve assemblies are not identical. And the valve guide is held in place with a compression spring. The trumpet itself is sealed at the bottom with an O-ring and at the top with a ½” PTFE gasket.

Group collector

The group collector is screwed into the bottom of the brewing group body. The valve guide assembly is almost identical to the top trumpet but has a square rod instead of a round rod and the valve guide is slightly longer than that of the top trumpet. This valve guide is also held in place with aspring. Note that this is a larger spring than the one at the top trumpet. To seal the group collector, a ½” PTFE gasket is used.

Drain valve

The drain valve is used to drain the wastewater. This is an identical valve guide assembly. But it has no shaft and the valve guide itself is much shorter. This valve is also held in place by aspring. Under the spring, however, there is a special drain valve-aerator that lets the wastewater through.

The lever assembly

The lever assembly can be screwed as a whole into the side of the brewing group. The main component is the brass cam. This part protrudes through the chrome cam holder. In this holder, there are 2 flat seals to seal the shaft. To exert uniform pressure on the seals, there is a brass sleeve which is held under tension by the cam spring, which is sealed by the end nut. At the end of the brass cam, there is a small lever which operates the complete brewing group.

How does the Faema E61 brewing group work?

The brewing group is connected with 2 tubes, the upper and the lower tube, with the HX. The upper tube comes from the top of the HX and delivers the warm water to the brewing group. The brewing group body is a block of chromed brass. This massive block needs to be heated up with the HX's water. When the water has cooled, it flows through the bottom tube back to the bottom of the HX. The advantage of using a large mass is that it is relatively temperature stable.

Before you want to start to make coffee you need to wait until the brewing group has heated up. Otherwise, the water temperature drops because it loses a lot of energy to the brass, which has not yet been heated to operating temperature.

The process of brewing

If you lift the lever and set it to the middle of full distance (i.e., do not activate the pump), the pre-infusion will start. That is, based on the pressure in the HX, the water slowly flows through the brew group into the coffee.

Valve positions

When the lever is at the fully open position, the cam has been rotated in the middle of the group. Since the cam is symmetrical, it pushes the top valve open. And it closes the bottom valve automatically, as it is pushed by the spring in the bottom valve to close. When the lever is closed again, the top valve closes. The bottom valve is opened and the outlet valve is also opened.

The flow of the water

If you want to start the brewing process, raise the lever to the max point. At this point, the pump starts to run. The water enters the top trumpet area through the top tube. The water flows through holes in the top of the top trumpet into the gigleur room. From the gigleur room, it flows through the gigleur itself. From there the water flows to the inside of the trumpet and towards the shower screen.

When the lever Is lowered, the remaining water flows to the group collector and to the drain valve, and then it is taken out from the brewing group.

The principle of the E61 brew group or derivative thereof is used by various brands such as: Vibiemme, Rocket, ECM Heildeberg, La Pavoni, Wega, San Remo, Grimac and more brands.