Espresso machine solenoid valves

Espresso machine solenoid valves

Since the invention of the coffee maker machine, all valves of a coffee espresso machine were operated manually. From the first vertical coffee machines to the lever espresso machines and up to the pump driven Faema e61. However, the introduction of the electronically controlled espresso machines has created the need to electronically control the valves as well.

How does a solenoid valve work?

There are two types of solenoid valves, one normally open (NO) and one normally closed (NC). With an NO, there is a constant flow (since it is open). When the electromagnet in the coil is activated, this coil closes, as long as the current is flowing. If the solenoid valve is an NC, there is no flow through the valve. When the solenoid valve is activated, the valve will open, as long as the current is flowing.

What is the use of a solenoid valve in an espresso machine?

Most solenoid valves are used for the following purposes:

- Filling the boiler;

- Brewing group;

- Water dispensing

Filling the boiler:

A lot of boilers have a stainless-steel water level probe. This probe is quite often mounted on top of the boiler and sticks into the water in the boiler. When the level regulator or the PCB detects that the water level is too low, the 2-way solenoid valve will open. Then the boiler fills up under water-line pressure. As soon as the water level reaches the probe again, the solenoid valve will close. This solenoid valve is quite often located on a filling valve. For some brands, these filling valves also have manual control if the solenoid valve is damaged.

Brewing group solenoid valve:

When the touchpad is pressed, the brewing process begins. The 3-way solenoid valve, which is located near or above the brewing group, opens. After completion of the brewing process, the solenoid valve closes again and the remaining water flows out of the outlet of the 3-way solenoid valve.

Water dispensing solenoid valve

This 2-way solenoid valve is mainly used for getting tea water. When a button or touch panel is pressed, the solenoid valve will open. If you press the button again, the valve will close.

Basic principles of an espresso machine solenoid valve

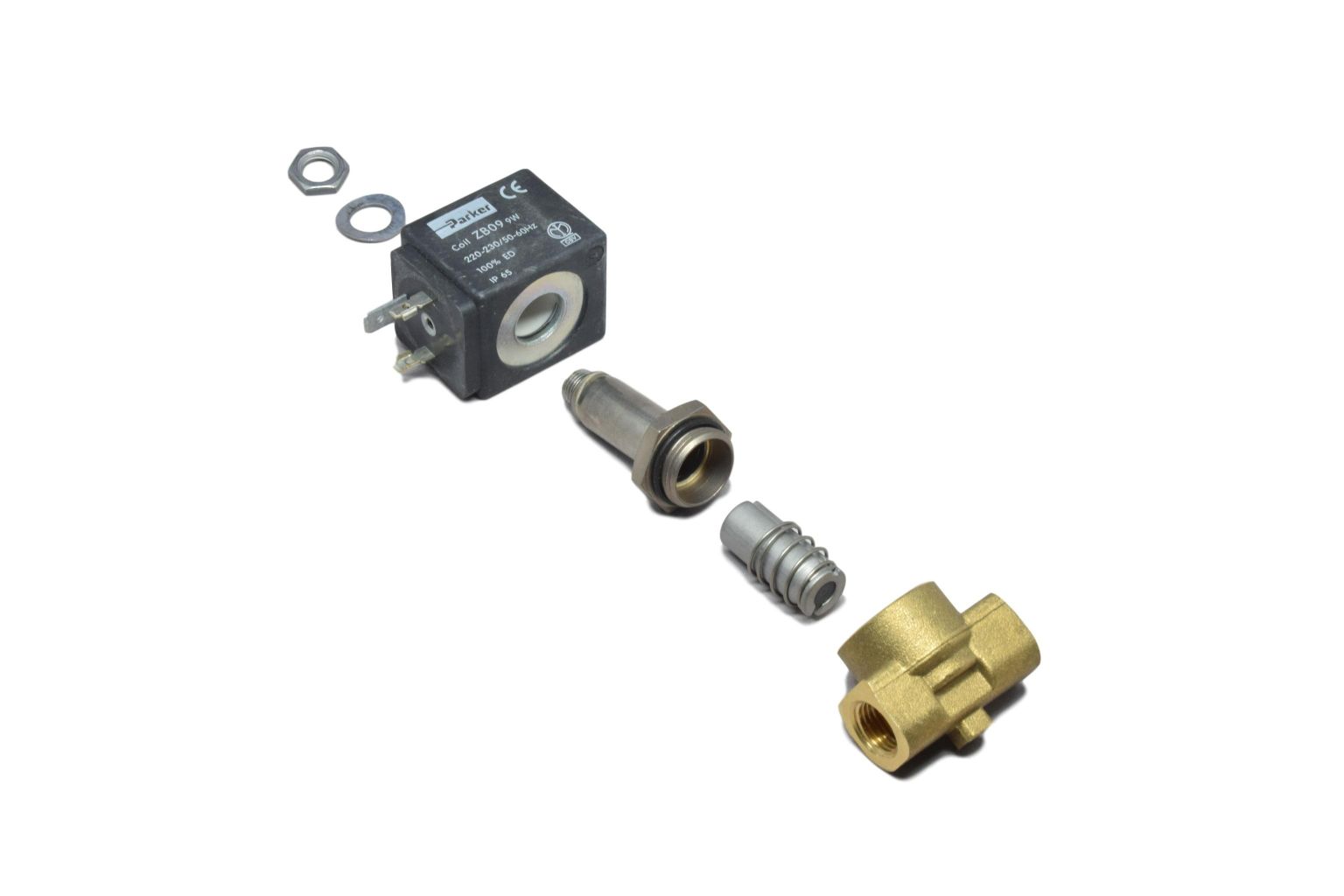

A solenoid valve consists of 6 components:

- The electromagnet

- The plunger

- The plunger spring

- The plunger gasket

- The main gasket

- The tube assembly

- The valve body

The valve body

The solenoid valve bodies are available in two material versions:

- NSF-graded brass

- stainless steel

There are also two types of valve body models:

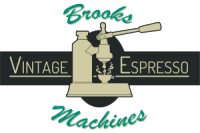

- The flange model. This valve is placed on a smooth surface (for instance a brewing group) and is attached to the surface with 4 screws. The flat surface is sealed off with 2 FKM rings.

- The thread model. This model has a thread on both sides. The most commonly used sizes for espresso machines are ¼” BSP-G and 1/8” BSP-G. The body can be fixed by screws to a body piece (the thread is inside the valve body). The solenoid valves need to be equipped with fittings to connect tubes to the valve. These fittings can be sealed off with copper gaskets.

The solenoid valve bodies all have a flow direction indicator. The flange model typically has a 1 and a 2 at the bottom of the valve body adjacent to the inlet and outlet. For the thread model, there is often an arrow on the side or bottom of the body indicating the flow direction.

The tube assembly

The tube assembly is a stainless-steel cylinder that serves as a guide for the piston and spring inside. In case of a 2-way valve, this tube is capped at the end. For a 3-way valve, this end is normally open to drain the wastewater.

This is a circular sealing ring on the tube assembly. When the tube assembly is screwed into the valve body this seal ring compresses and seals the solenoid valve.

The plunger gasket

The plunger gasket is located in the bottom of the plunger. This gasket is a part that cannot be serviced. The gasket is compressed to a valve seat of the valve body to seal it.

The plunger spring makes the difference between an NC and an NO solenoid valve. With an NC this spring pushes the plunger onto the valve seat, which allows no flow. When the solenoid valve is activated, the magnetic field raises the plunger and opens the valve. When the coil is deactivated the solenoid valve closes again.

With an NO solenoid valve, the opposite is the case. This valve is always open, ensuring a constant flow. When the coil is activated, the plunger falls down and seals the valve. However, this type of solenoid valve is not common in espresso machines.

The plunger

The plunger is made of ferritic stainless steel (this is a magnetic stainless-steel variant, opposed to commonly used “traditional” stainless steel, which is not magnetic). This plunger has a gasket in the bottom to seal the valve seat. On top of the plunger, there is a neck in which the spring is located.

The electromagnet

The electromagnetic coil goes over the tube assembly. When there is an electromagnetic current flow through the copper winding in the coil, the coil moves. So, it will open or close the plunger.

The list above contains the basics of what a solenoid is and how it works. However, there are many more specifications for solenoid valves, because not every one of them is equally suitable in every location.

There are 6 manufacturers of solenoid valves that are widely used in espresso machines:

These brands make a variety of espresso machine solenoid valves. If you are looking to replace your own solenoid valve on your machine, you need to check for the following things:

- Brand – yes, a lot of solenoid valves are exchangeable. You must, however, look at the flange type and the screw fastenings. Because these can vary.

- Fitting size – if you are using a solenoid valve which has a fitting, look closely if you have the right thread size.

- Orifice – the hole diameter may vary depending on the model. If you use a smaller diameter orifice, the machine may not work as before.

- Working pressure – not all solenoid valves can work in the same pressure range. To fill the boiler, normally only the water pressure of the main pipe has to be taken into account, which may vary depending on the region or country. However, if you are using a solenoid valve for a brewing group, they can endure working pressures that are much higher.

- Working temperature.

- Adjustability – there are some models of espresso machines that use an adjustable solenoid valve.

- Voltage, current and Hz – most solenoid valves operate with 220-240V at 50-60Hz AC. But there are also versions which operate at 24V DC or 110V AC at 50Hz (of course for the US market). You will find this data on the side of the coil of the solenoid valve.